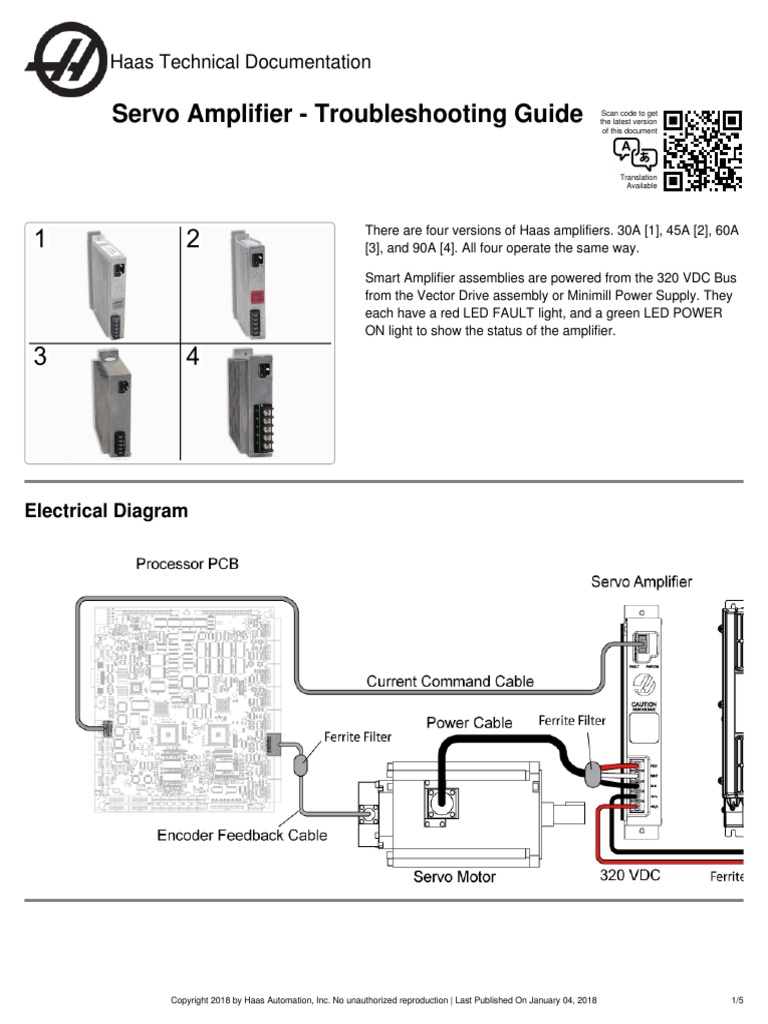

The servo amplifier, an intricate component within motion control systems, serves as a linchpin for facilitating precise motor function. It does so by regulating voltage and current to drive the servo motor effectively. Yet, one of the most perplexing issues that can arise is the ominous absence of lights—specifically, no LEDs illuminating the device’s faceplate. This situation warrants a deeper exploration, as it may signify an unseen problem lurking within the system.

Understanding the implications of no LED illumination involves deciphering both the functional and communicative roles these indicators play. LED lights often signify the operational status of the servo amplifier, offering insights into its health and functionality. Thus, encountering dead lights may unleash a cascade of questions about system integrity and performance.

1. First Impressions Matter: The Initial Diagnostics

When faced with an unlit servo amplifier, the instinctive reaction may involve jumping to conclusions about catastrophic electronic failure. However, initial diagnostics should start with a basic inspection of power supply connections. A loose or disconnected power source may be the simplest explanation for the incipient darkness. Verifying voltage levels with a multimeter can illuminate whether the unit is receiving adequate power. If the power supply checks out, further investigation is warranted.

Moreover, ensuring that all connectors are free from oxidation or damage is paramount. Corrosion can impede the flow of electricity, leaving your amp in a state of limbo. Thus, every connection point must be scrutinized meticulously to mitigate this potential oversight.

2. Exploring the Internal Dynamics: Components at Play

Beyond the power supply, the internal components of the servo amplifier warrant examination. Capacitors, resistors, and circuit boards can be subjected to wear and tear over time. A burnt-out component may lead to the failure of the entire unit, signifying that circuits meant to drive the amplifier are compromised. Understanding the schematic diagram of your specific model can provide crucial insights, allowing you to trace back to the root of the problem.

Furthermore, thermal overloads can irrevocably alter the performance of a servo amplifier. A heat-sensitive element may shut down in response to excessive temperatures, resulting in a complete lack of LED feedback. Monitoring thermal thresholds can be invaluable in preventing further failures.

3. The Role of Protective Features: Safety Disconnects

In certain instances, the absence of LED signals may indicate that the servo amplifier has engaged its safety disconnect features. Modern servo amplifiers often contain advanced monitoring systems designed to protect both themselves and the connected servo motor from operational anomalies. Overcurrent conditions, for example, trigger a protective shutdown, resulting in the very scenario where no LEDs light up. Understanding these fail-safes can shift your perspective on what might otherwise appear to be a malfunction.

Consequently, resetting the servo amplifier according to the manufacturer’s guidelines can be an essential next step. This process often involves turning off power, allowing the unit to cool, and then powering it back on. If the LED lights return, the protective protocols have successfully mitigated a potentially detrimental situation.

4. Insights from User Manuals: The Knowledge Resource

User manuals often provide a treasure trove of troubleshooting options tailored specifically to the model in question. They may also delineate LED behavior that might not be immediately apparent. For instance, some servo amplifiers are designed to exhibit specific flashing patterns to denote error types or operational statuses. Familiarizing oneself with this documentation can be transformative, providing clarity where confusion initially reigned.

Consulting the manual can also uncover information on firmware updates. Outdated firmware may cause functionality issues that result in no LED illumination. Timely updates can restore communication pathways and breathe new life into older units.

5. External Influences: Environmental Factors

Beyond the circuitry itself, environmental conditions can dramatically influence the operational status of electronic devices. Dust accumulation, moisture ingress, or extreme temperature variations can upset the delicate balance of components within a servo amplifier. These external factors may not only contribute to LED failure but can produce lingering effects that compromise performance over time.

Implementing a preventative maintenance schedule designed around clean environments can reduce the infiltration of dirt and moisture. Additionally, maintaining optimal environmental control—such as temperature regulation—can prolong the lifespan of the servo amplifier.

6. Seeking Professional Insight

In situations where internal diagnostics yield little to no results, seeking expert evaluation provides a final recourse. Seasoned technicians possess the knowledge and experience to dive deeper into complex issues that lie beneath the surface. They can conduct comprehensive tests beyond the typical user toolbox, shoring up any potential inadequacies that may remain undetected. Trusting an authority in the field can often transform confusion into clarity.

Conclusion: The Path Forward

The enigma of no LEDs on a servo amplifier serves as a compelling reminder of the intricate ballet of electronic components at play. Each unlit LED could be a whisper from the machine, urging an inquisitive mind to engage more deeply with the functionalities that lie beneath the surface. By embarking on a systematic exploration—from power supply verification to environmental assessment—users can cultivate a perspective that transforms troubleshooting into a precise art form. A once-silent amplifier may yet hum back to life, illuminating not merely the device but the journey of understanding behind it.