In the world of shipping and logistics, acronyms and jargon abound. One term that frequently pops up yet remains enigmatic for many is “ROC.” What does ROC stand for in the context of shipping and logistics? Is it merely another abbreviation in a sea of shorthand, or does it hold significant meaning that can influence operational processes? Let’s embark on a quest to unravel the intriguing layers of ROC.

To commence, it’s essential to clarify that ROC can have multiple interpretations, depending on the specific sector within logistics. The most common definition of ROC is “Regional Operation Center.” This term refers to a centralized hub that coordinates activities and resources across a specific geographical area. Such centers are indispensable for companies that operate on a large scale, facilitating a streamlined approach to logistics management. But how does a Regional Operation Center enhance the logistics framework?

A Regional Operation Center acts as the nerve center for logistics operations within its jurisdiction. These facilities enable companies to monitor, control, and optimize the movement of goods through a well-defined region. They combine data analytics with operational efficiency to ensure timely deliveries, reduce costs, and improve customer satisfaction. However, one might wonder: what are the inherent challenges of establishing such an efficient ROC?

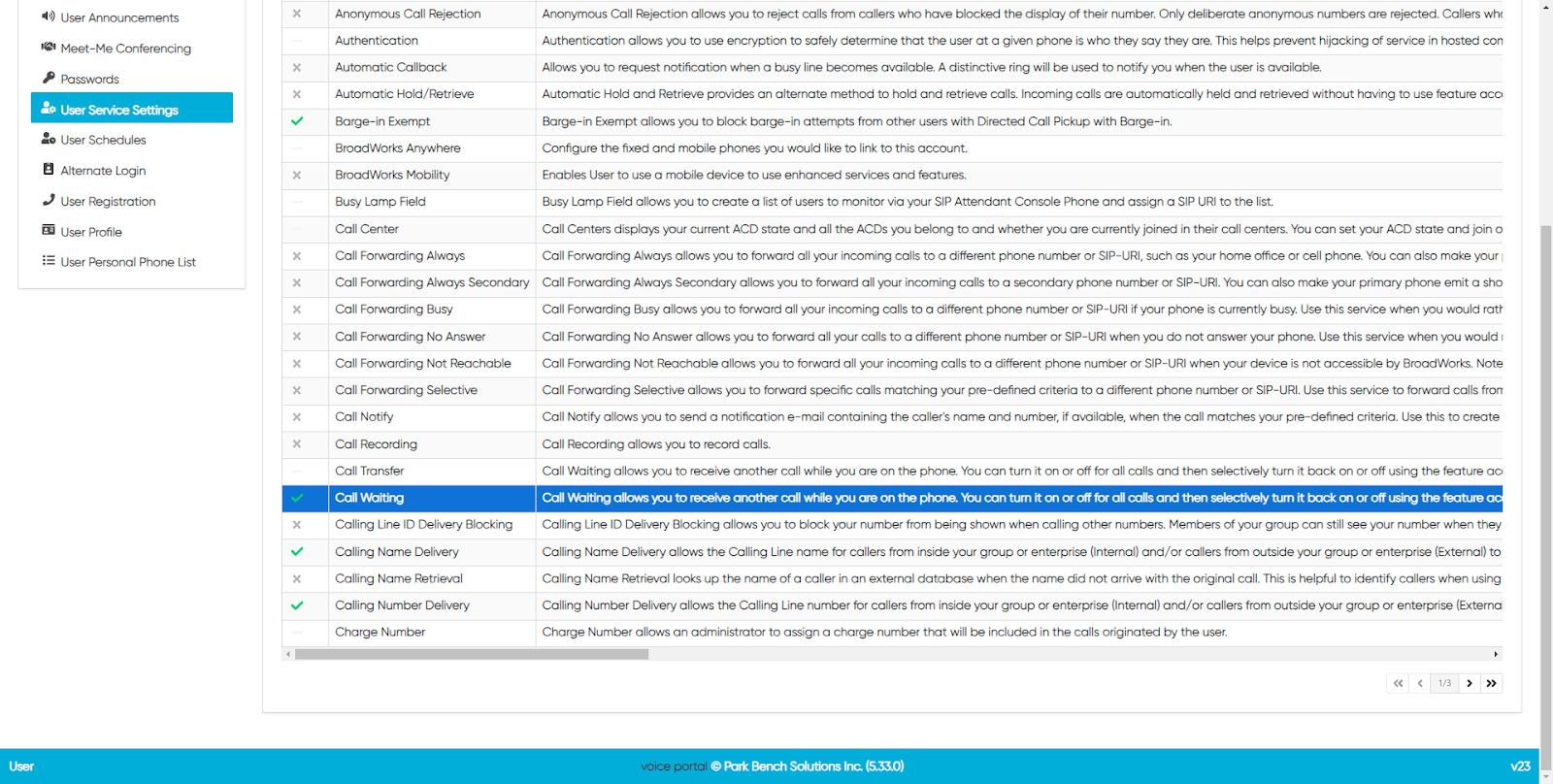

Creating an effective Regional Operation Center is akin to piecing together a complex puzzle. Numerous factors contribute to its success, most notably technology, manpower, and strategic location. Technology plays a pivotal role, as modern logistics heavily relies on sophisticated software systems for tracking, inventory management, and route optimization. Imagine trying to navigate a sprawling city without GPS; it would be quite the challenge, right? Now multiply that by the intricacies of logistics operations, and you begin to appreciate the weight of technological integration within an ROC.

Manpower is another critical element. Having a skilled workforce trained to adapt to various logistical challenges is essential. Yet, with the ever-changing landscape of supply chain demands, ensuring that employees are continuously educated and equipped with modern practices poses an ongoing challenge. What happens when a crucial team member is absent, or when unexpected spikes in demand occur? These are the potential roadblocks logistics companies face daily.

Strategic location, moreover, cannot be overstated. An ROC needs to be situated within a geographic area that maximizes accessibility to major transport routes. Proximity to shipping ports, railroads, and highways can drastically reduce transit times and costs. But consider this: what if geopolitical tensions arise or unforeseen natural disasters affect transport routes? How does an ROC mitigate these risks to maintain the flow of goods?

It’s these myriad challenges that make the operational excellence of a Regional Operation Center both vital and complex. Yet, the benefits of a well-orchestrated ROC extend beyond mere centralization of operations. For instance, the procurement and distribution of resources can be significantly enhanced. By leveraging data analytics, ROCs can predict demand trends, manage inventory strategically, and ensure that goods arrive just in time without inflating costs through overstocking.

The role of an ROC also extends to relationship management. Building strong rapport with local suppliers and distributors is crucial for seamless operations. After all, in the realm of logistics, one’s partner can dramatically influence overall efficiency. However, what recourse does a logistics provider have when unexpected challenges create friction within these partnerships?

A mature ROC framework allows for adaptable contingency mechanisms. Lean methodologies can be employed to minimize waste and pivot operations when necessary. Furthermore, integrating feedback loops can encourage communication among stakeholders, paving the way for proactive problem-solving strategies. This cultivation of adaptability is particularly crucial in an industry characterized by rapid change.

As we delve deeper into the intricacies of ROCs, another facet worth exploring is the impact of globalization on regional operations. As companies expand their reach and intercontinental supply chains become the norm, the challenges faced by Regional Operation Centers become multifold. Enhanced competition and varying regulatory requirements across borders complicate decisions related to customs, tariffs, and compliance.

Therefore, ROCs must integrate localized knowledge with a global perspective. Adapting practices to remain agile in the face of shifting international trade policies—what an intricate balancing act! Logistics professionals must continuously monitor global trends, economic shifts, and technology advancements to maintain their Competitive advantage.

Moreover, sustainability has increasingly become a focal point within the logistics sphere. A modern ROC must strive for eco-friendliness without sacrificing efficiency. This calls for innovative solutions that can reduce carbon footprints while promoting responsible logistics practices. But how does one measure success in such a dynamic relation? Finding the right metrics amid an evolving set of priorities poses yet another challenge for operational managers.

In summary, the term ROC in shipping and logistics encompasses much more than an abbreviation; it signifies a pivotal operational strategy that can fundamentally influence a company’s logistics efficiency. From managing complex data systems and workforce dynamics to the strategic location of hubs and sustainable practices, Regional Operation Centers are essential for cultivating a resilient logistics framework. As companies continue to expand and face unforeseen challenges, the importance of ROCs will only grow. Will your organization be ready to navigate this exciting and intricate landscape?