The automotive world is a complex tapestry woven from myriad components, systems, and codes that govern the intricate functioning of modern vehicles. Among this lexicon resides the term “TXM,” a designation which encapsulates a plethora of meanings depending on the context in which it is employed. To the layperson, automotive codes might seem like an enigma wrapped in a riddle, but delving into their significance reveals a treasure trove of information essential to understanding vehicle performance, diagnostics, and maintenance.

TXM commonly refers to Transmission Module or Transmission Control Unit in automotive terminology. These components play a vital role in the seamless interplay between engine performance and gear shifting, ultimately influencing the efficiency and operability of the vehicle as a whole. As such, TXM is not merely a buzzword; it correlates directly with a vehicle’s drivability, fuel economy, and user experience.

Understanding the significance of TXM begins with an exploration of its function within the broader framework of automotive engineering. The Transmission Control Unit is the brain behind the automatic transmission system, orchestrating the delicate choreography of gear shifts to optimize power delivery and fuel consumption. It accomplishes this through a series of electrical commands that adjust the hydraulic pressure within the transmission, ensuring that each gear engages at the precise moment for peak performance.

Moreover, the TXM’s functionality extends far beyond mere shift timing. In modern vehicles, these modules are often equipped with advanced algorithms that adapt to driving conditions—such as varying loads, terrain, and driver behavior—enhancing the vehicle’s responsiveness. Drivers experience smoother transitions and improved acceleration, culminating in a more gratifying driving experience.

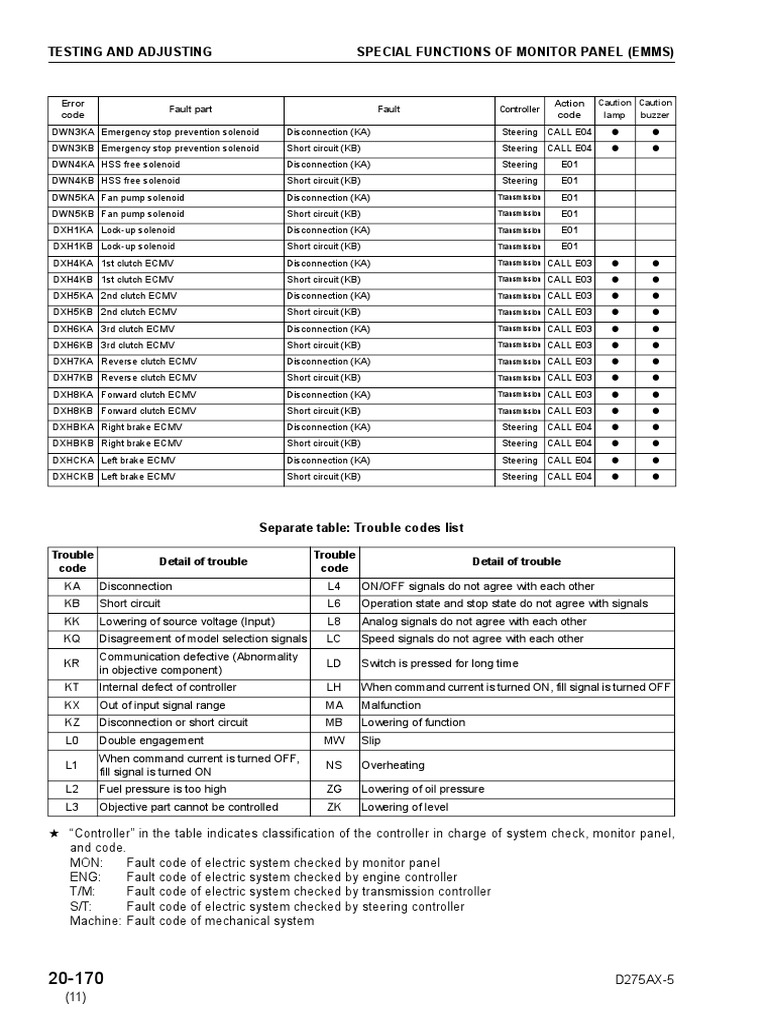

The complexity of TXM systems also means that they are susceptible to various issues. Understanding the potential pitfalls of transmission control units is invaluable for vehicle owners and automotive technicians alike. Common malfunctions can manifest as erratic shifting, delayed engagement, or even transmission failure. These symptoms often trigger the vehicle’s onboard diagnostic system, which subsequently generates specific trouble codes to aid in identifying the source of the problem.

When a driver encounters a trouble code associated with the TXM, automotive technicians usually turn to the On-Board Diagnostics (OBD-II) system. This system communicates the specific failures and operational anomalies through standardized codes. For instance, codes such as P0700 indicate a general transmission problem, while codes like P0730 can denote incorrect gear ratios. These codes serve as a vital toolkit for diagnosis, allowing for the pinpointing of faults that could otherwise remain obscured.

As the automotive landscape evolves, so does the technology behind transmission modules. The advent of electric and hybrid vehicles introduces new dynamics to the TXM paradigm. In these vehicles, the TXM may interact with electric motors, regenerative braking systems, and intricate energy management systems, requiring an even higher level of sophistication. The intricate networks of data flow that correlate engine performance with electric systems necessitate a TXM that can adapt and recalibrate in real-time for optimal efficiency and power distribution.

To the enthusiast, the implications of TXM technology pave the way for exciting advancements in vehicle performance modifications. Tuning enthusiasts often experiment with various TXM chips or software upgrades that can recalibrate shifting patterns and optimize engine parameters. Such enhancements can yield profound improvements in drivability and acceleration, allowing drivers to tailor their vehicles to align more closely with their performance aspirations.

However, with the promise of enhanced performance also comes a caveat: excessive modifications can lead to unforeseen complications. Alterations to the TXM can disrupt the careful balance of the vehicle’s systems, leading to potential malfunctions. Thus, while the allure of performance tuning is significant, it is imperative that adjustments are made with a profound understanding of the underlying systems.

Beyond performance upgrades, TXM understanding also extends to the realm of preventative maintenance. Awareness of transmission fluid quality and levels can significantly affect the lifespan of the TXM and the transmission as a whole. Regular fluid changes and inspections of wiring harnesses are prudent practices that mitigate common problems that can lead to premature failures. By taking an informed, proactive approach, vehicle owners can extend the longevity of their transmissions and ensure seamless performance.

Moreover, the integration of TXM systems fosters a deeper connection between the driver and the vehicle, showcasing the transformative nature of automotive technology. As vehicles become increasingly reliant on software and electronic components, the driver is granted access to a wealth of data through vehicle interfaces and mobile applications. Information regarding shifting patterns, drivability parameters, and even diagnostic insights become readily available, enhancing the overall ownership experience.

In conclusion, TXM—a term encapsulating the essence of transmission control technology—is foundational to the automotive mechanical lexicon. As it intertwines with the broader fabric of automotive innovation, understanding the implications of TXM becomes essential for anyone with a vested interest in vehicular operation, whether for troubleshooting purposes, performance enhancements, or routine maintenance. Knowledge of TXM technologies empowers drivers and technicians alike to engage more fully with their vehicles, making informed decisions that pave the way for an enhanced driving experience.