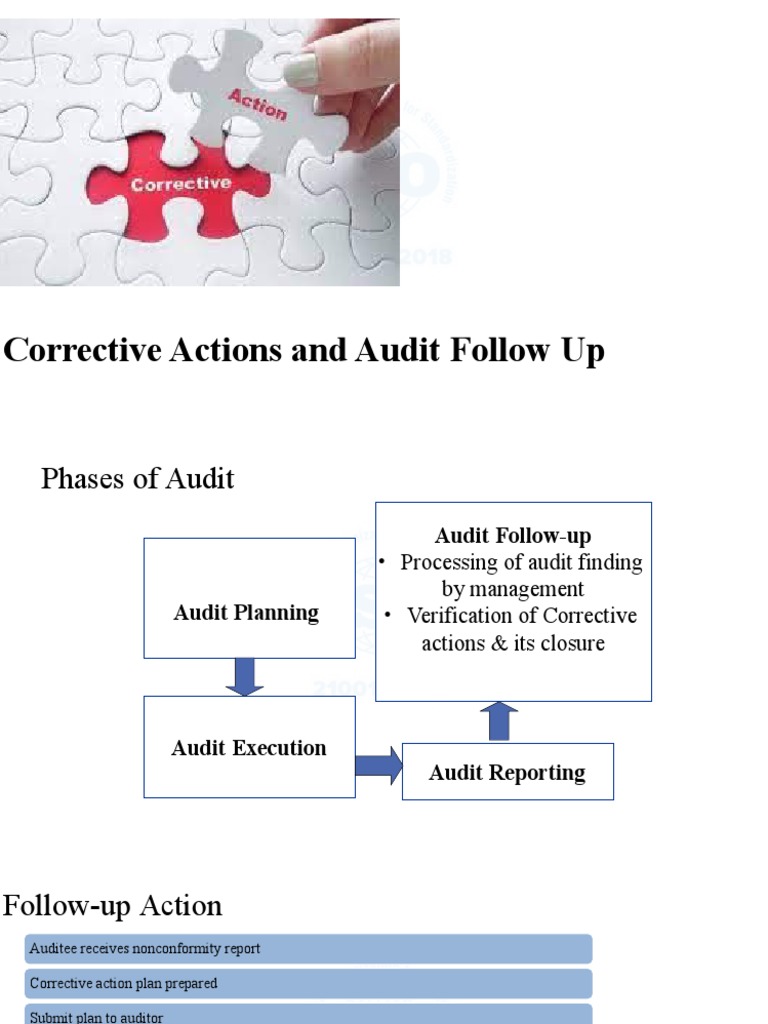

In the realm of organizational management and quality assurance, the term “corrective action” serves as a linchpin for sustained efficacy and excellence. A corrective action is fundamentally any measure designed to rectify a identified deficiency or nonconformity within processes, products, or operations. Below, we delve deeply into an illustrative example of corrective action, elaborating on various content that readers can expect to encounter regarding its implementation, methodologies, and significance.

Understanding the Necessity of Corrective Action

Corrective actions are predicated on the identification of a problem, typically emerging from quality audits, customer feedback, or performance assessments. Such actions are not mere band-aid solutions; rather, they are intricate strategies encompassing a thorough analysis of root causes, fostering a culture of continuous improvement. Consider a manufacturing company where substandard product quality has resulted in increased customer complaints. The subsequent corrective action must not only resolve the immediate quality concerns but should also identify the systemic issues that allowed such deficiencies to arise. This dual focus underpins the efficacy of any corrective initiative.

Crafting an Effective Corrective Action

The formulation of an effective corrective action plan involves several pivotal steps:

- Problem Identification: Clearly defining the problem at hand is paramount. This often involves gathering data, consulting with stakeholders, and reviewing incident reports to attain a holistic understanding of the issue.

- Root Cause Analysis: Employing methodologies such as the “5 Whys” or Fishbone diagram to unearth the underlying factors contributing to the issue. For example, a car manufacturing company might discover that defects in the paint finish stem from inadequate employee training.

- Action Development: Once the root cause has been established, organizations need to develop actionable steps to address it. This may include training sessions, upgrades to equipment, or revised processes.

- Implementation: The selected corrective actions must be integrated into the operational framework. This phase often requires concerted effort and engagement across various departments to ensure successful deployment.

- Monitoring and Verification: After the implementation, organizations should monitor the results. This could involve collecting performance metrics or following up with customer surveys to ensure that the corrective action has alleviated the problem.

Example Scenario: A Manufacturing Case Study

To illustrate the application of corrective action, let us explore a scenario within a fictional automotive parts manufacturer, “AutoParts Inc.” Following a routine quality inspection, the company discovers that a significant batch of brake pads fails to meet safety standards. The immediate consequence is a recall announcement, leading to potential financial losses and reputational damage.

In response, the management team undertakes the following corrective actions:

- Identifying the Problem: Recognizing the defect during quality control led to an in-depth examination of the production processes to pinpoint the lapse.

- Root Cause Analysis: Through the implementation of the Fishbone diagram, it is uncovered that the defect originates from a malfunctioning piece of machinery combined with insufficient operator training during a period of unexpected turnover.

- Action Development: Corrective actions include upgrading machinery components while instituting a refreshed training program designed to enhance operator competency.

- Implementation: The company engages in a phased implementation of the training and maintenance protocols while ensuring communication across the teams involved in production.

- Monitoring and Verification: To ascertain the effectiveness of these corrective measures, AutoParts Inc. tracks the performance metrics of subsequent production batches and compares them with historical data, achieving notable improvements.

Broader Implications and Significance

Corrective action transcends mere compliance or problem-solving within organizations; it embodies a fundamental ethos of proactive management and accountability. Organizations that prioritize corrective action not only bolster their operational integrity but also enhance customer trust and satisfaction. By addressing issues effectively, they reinforce their commitment to quality, which has far-reaching implications for brand loyalty and market competitiveness.

Challenges in Implementing Corrective Actions

While the framework of corrective action is structured, organizations often encounter challenges in its implementation.

- Resistance to Change: Employees may exhibit reluctance toward new processes or training programs, driven by inherent inertia or a lack of understanding.

- Resource Allocation: Allocating sufficient resources, both in terms of time and finances, can pose significant hurdles, especially in smaller organizations.

- Measurement Difficulties: Evaluating the effectiveness of corrective actions can be complex and requires robust metrics for analysis.

The Future of Corrective Actions

As industries evolve and embrace technological advancements, the landscape of corrective action is also transforming. Organizations are increasingly leveraging data analytics and artificial intelligence to enhance their corrective action strategies. Predictive analytics can foresee potential failures, enabling preemptive corrective measures that mitigate risks before they escalate into substantial problems.

In conclusion, corrective actions are an indispensable aspect of organizational excellence. They encapsulate a proactive approach to quality management, reinforcing the significance of continual improvement. By understanding the intricacies and applications of corrective action, organizations not only rectify deficiencies but also fortify their operational foundations for sustainable growth.