In the fast-paced world of logistics and shipping, each abbreviation or term holds significance that can be both perplexing and enlightening. One such term that frequently crops up in the realm of United Bag tracking notes is “QOH.” For those who find themselves navigating these intricate waters—whether as a business owner, a freight manager, or a curious consumer—the mere mention of QOH sparks a multitude of questions. What does it truly signify? How does it affect the logistics chain? And why should one pay attention to this seemingly innocuous abbreviation?

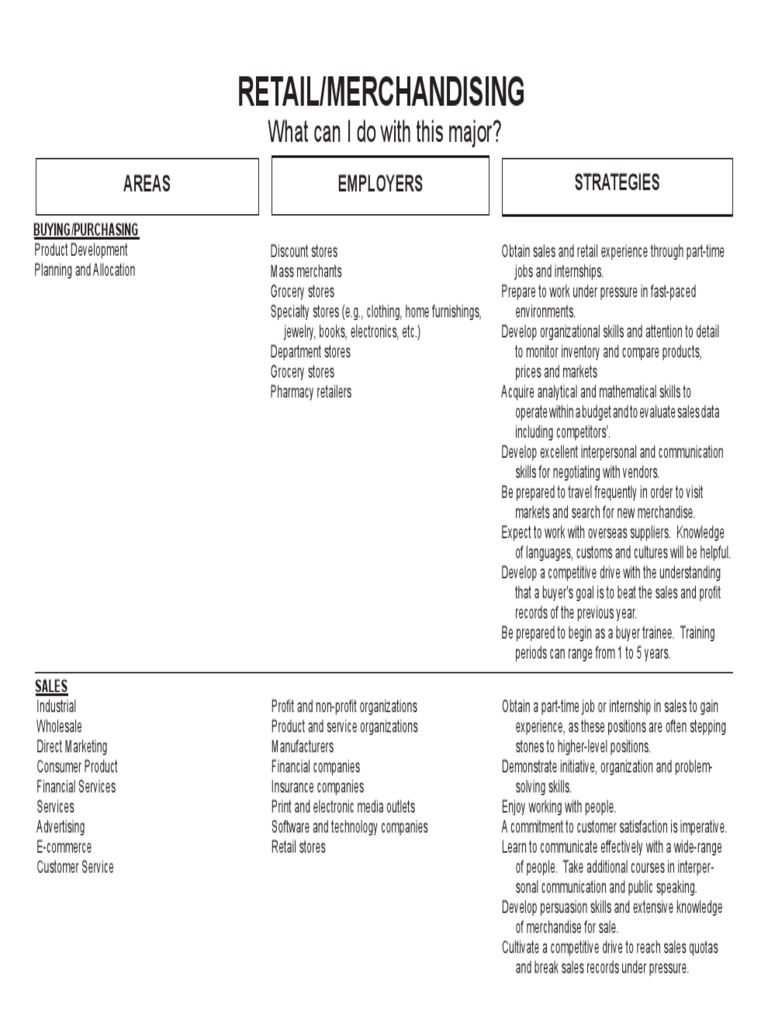

The acronym QOH stands for “Quantity On Hand.” This term is imperative for understanding the state of inventory management and tracking within logistics. It provides a snapshot of how many units of a product or material are readily available. For companies like United Bag, which specializes in manufacturing and distributing various types of bags and packaging solutions, knowing the QOH is crucial. After all, the ability to swiftly fulfill orders hinges upon the precise knowledge of available inventory.

As one delves deeper into the concept of QOH, the implications become manifold. Imagine a bustling warehouse where hundreds of items are stored. Without an accurate count of what’s on hand, the entire system of order fulfillment can collapse like a house of cards. QOH serves as the backbone of this operational framework. It enables businesses to avoid backorders, excessive lead times, and ultimately dissatisfied customers.

However, the relevance of QOH transcends mere inventory acknowledgment. It embodies a promise of efficiency. For instance, when a warehouse manager examines the QOH noted in tracking reports, it allows for informed decision-making regarding reorders and stock levels. This approach protects against the double-edged sword of overstocking, which can lead to wasted resources, and understocking, which often results in missed sales opportunities.

Incorporating technology into the QOH assessment can further revolutionize operational capacity. With sophisticated inventory management software, tracking QOH can be automated. This substantial shift not only provides real-time updates but also enhances forecasting accuracy. Applying advanced algorithms to historical data streams can predict future inventory needs based on trends and seasonal fluctuations. The outcome is a seamless flow from production to shipment, transforming inventory from a mere statistic into a strategic asset.

But why should consumers concern themselves with this term? When engaging with United Bag, whether procuring materials for a large project or purchasing bags for personal use, understanding QOH can offer pivotal insights into order timing. For the astute buyer, the visibility of QOH enables better planning. Knowing what’s readily available encourages smarter purchase decisions, thereby curtailing delays in critical timelines.

Furthermore, analyzing QOH can also indicate the company’s operational robustness. A healthy QOH suggests that the business can withstand market fluctuations and volume spikes without compromising service. Conversely, a low QOH may raise red flags and lead to inquiries about supply chain stability. Thus, the keen-eyed consumer can identify a reputable partner, informed by the nuances hidden within the numbers.

As we venture further into the labyrinth of logistics terminology, it becomes apparent that QOH does not operate in isolation. Alongside other concepts, such as JIT (Just-In-Time) inventory management and safety stock, QOH interacts and influences broader strategies. For instance, JIT methodologies aim to minimize inventory holding costs by receiving goods only as they are needed in the production process. However, the effectiveness of JIT fundamentally hinges on accurate QOH levels. If the QOH is underestimated, the JIT model may falter, leading to operational bottlenecks.

In today’s interconnected world, visibility is more crucial than ever. Technologies such as RFID (Radio Frequency Identification) and IoT (Internet of Things) have revolutionized inventory tracking. These enhancements allow for precise, real-time data collection that informs QOH assessments. With such capabilities, stakeholders can achieve a holistic view of their inventory landscape, invariably leading to more strategic operational choices.

On a broader scale, the implications of QOH ripple beyond individual businesses. They influence entire supply chains. For manufacturers, understanding the QOH in relation to suppliers can dictate order rhythms and production schedules. A shift in one entity’s QOH can precipitate challenges up or down the chain. Thus, collaboration and communication between partners become paramount. Transparent QOH reporting enables all parties to synchronize efforts and expectations.

As we ponder the significance of QOH in United Bag tracking notes, we arrive at larger conclusions. The concept is not merely administrative but emblematic of a culture that values efficiency, foresight, and customer satisfaction. It prompts a re-evaluation of how we perceive logistics—not as a series of disconnected events but as a cohesive continuum underpinning success.

In summary, QOH is far more than just a notation on a tracking report. It represents a fundamental aspect of logistics—a critical indicator of health within supply chains. Embracing and understanding it opens the door to myriad opportunities for efficiency, innovation, and operational excellence. This holistic perspective invites all stakeholders to engage with their inventory and partners profoundly. Thus, the invisible thread of QOH stitches together various elements of the logistical tapestry, transforming it from a mere transactional experience into a strategic alliance for thriving in an ever-evolving market landscape.